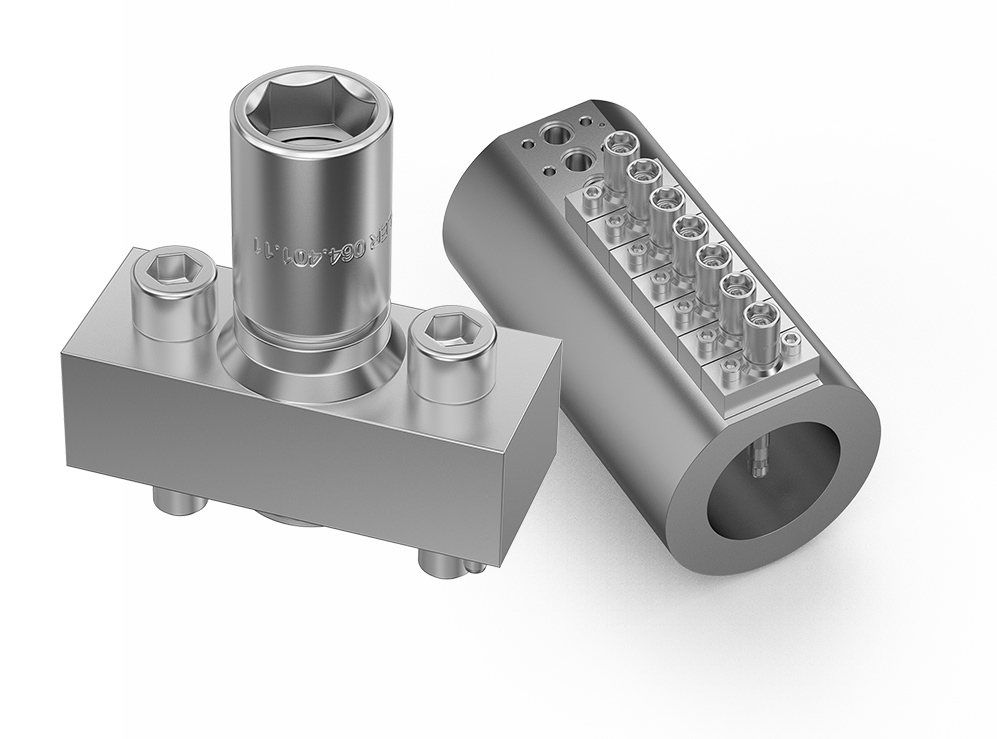

| The new nozzle brackets For better headers |

Standardized proven design for greatest design flexibility

Fast and efficient header design process

Tension-free bracket mounting on flat surface

Costly cracked header failures avoided

Increased operation safety and improved surface quality

Reduced downtime, maintenance cost savings

Features

Advantages

User benefits

Minimum nozzle pitch for MiniSCALEMASTER

Nozzles can now be realized without hesitation (40 mm with special nut, 43 mm with standard nut)

Available in any tailored length between 55 and 300 mm in 1,0 mm increments

Available also for chevron header designs

Lowest spray heights for maximisation of impact can be realized

Welding of nipples eliminated

Perfect nozzle positioning and alignment on header

All kinds of headers possible

Fast and cost effective repair of header

Greatest design flexibility

Single source for all relevant nozzle components

Costly cracked header failures avoided

Increased operation safety and improved surface quality

“Plug and spray” solution with all nozzle components from a single source

Reduced downtime, maintenance cost savings